ROOF PURLINS

Types of steel purlins

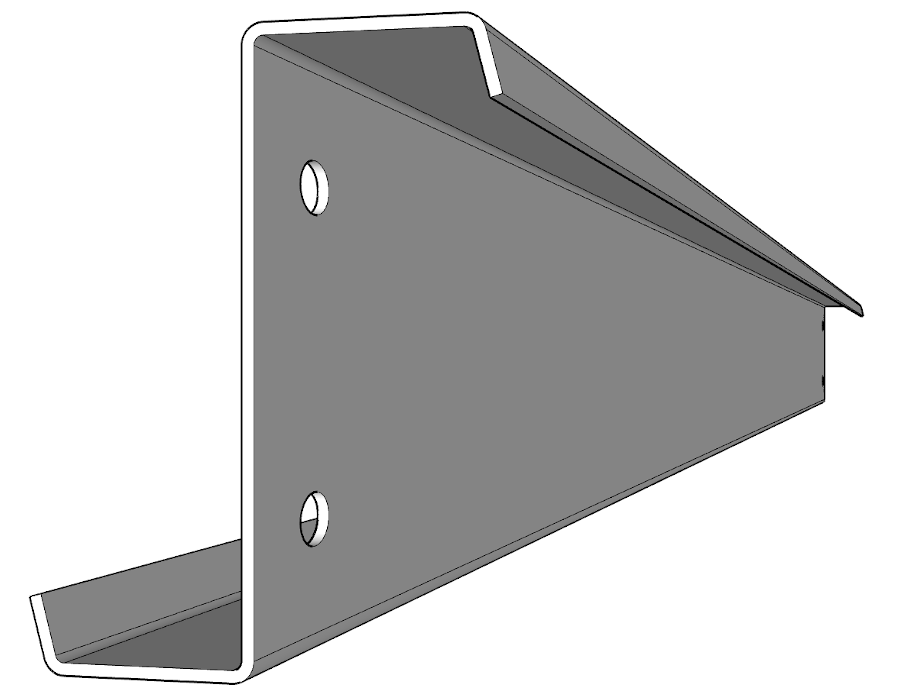

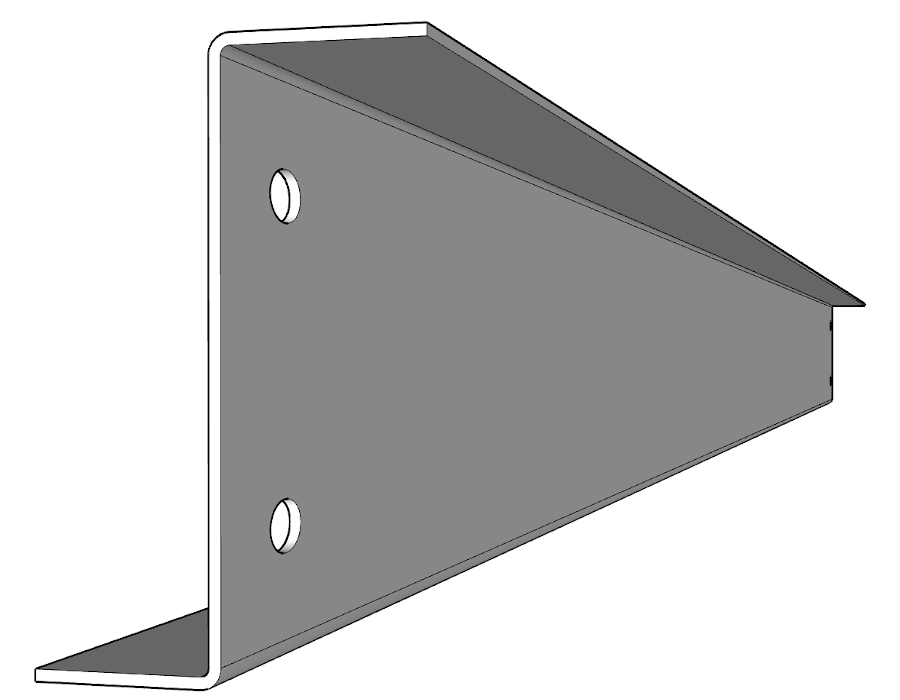

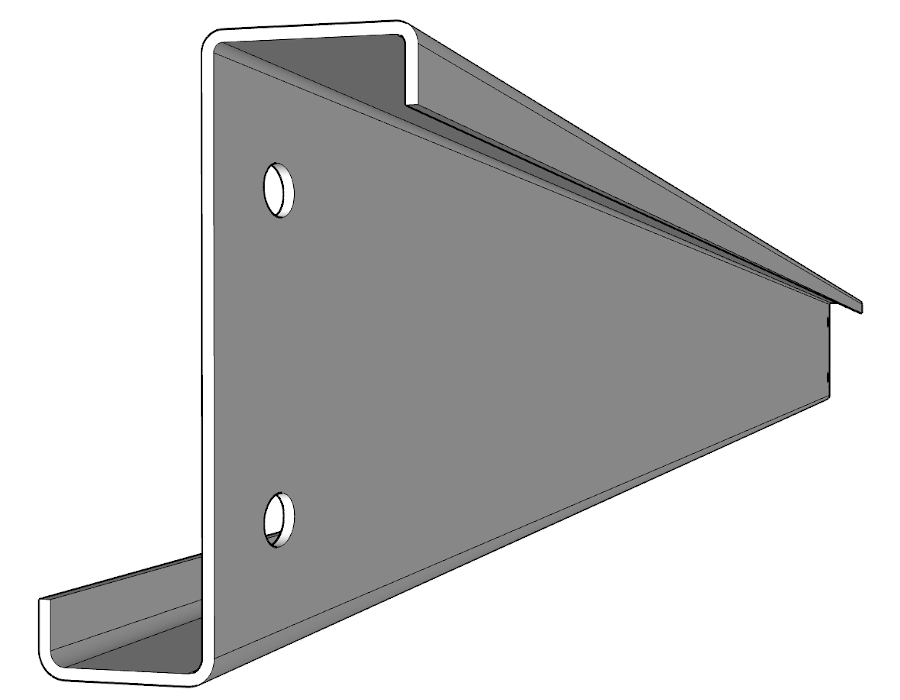

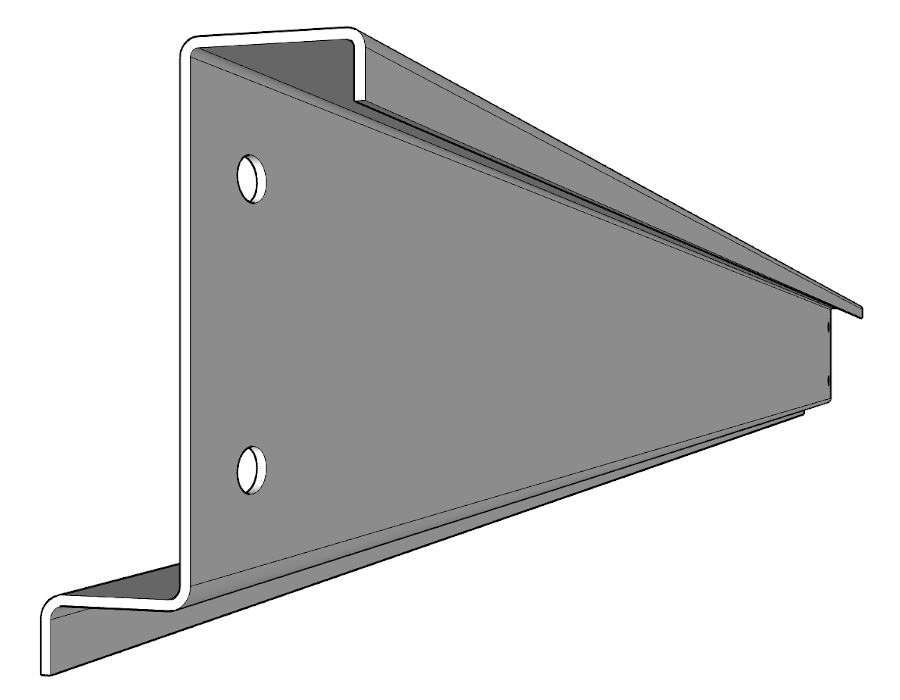

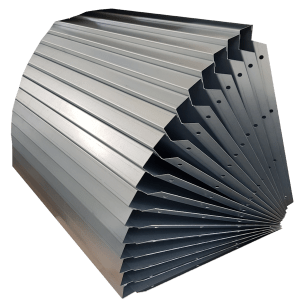

Schrag purlins

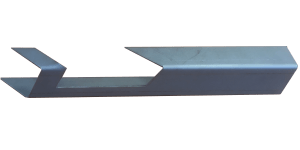

Purlins bent 2x

Purlins bent 4x

Purlins with a drip

Cold-formed purlins are an excellent alternative to purlins made of hot-formed sections. They are characterized by a much lower weight, which allows to reduce the weight of the structure and facilitates assembly. Cold-formed Z-section purlins, thanks to the use of appropriate cross-section dimensions, can be overlapped over the supports, creating a multi-span beam of any length. This joint also doubles the cross-section in places where it is most strained. Z-section purlins are also successfully used as single-span beams.

In the modern construction of steel industrial halls, the cold-formed purlin system we offer is a cost-effective alternative to traditional hot-formed profiles. The cold-formed purlins offered by Schrag have optimized shapes, which allows to minimize their weight, as well as the costs of transport and assembly. The dimensions of the cross-section and the thickness of the profile sheet, from which the cold-formed purlins will be made, depend on their spacing, as well as on the frame spacing and the loads that occur on the roof.

To meet the expectations of our customers, we leave at your disposal an experienced design team, which, thanks to an individual approach to each project, proposes the most effective solutions, which most importantly are following applicable standards and technical knowledge.

We know what is important to our customers

Thanks to the good organization of our company and modern machinery park, we provide our customers with professionalism, flexibility, quality and satisfaction.

What distinguishes our company:

- High dimensional accuracy of purlins obtained through the use of state-of-the-art unrolling and profiling devices, punching machines and CNC press brakes

- Own design team with extensive knowledge and experience in the field of static and strength calculations of cold-formed profiles

- Possibility of marking with the CE mark in accordance with the PN EN 1090 standard

- Deliveries following the construction schedule

Production lengths up to 16,400 mm.

To optimize the design and selection of purlins, you can use our software Schrag Lite >>.

Sheet metal parameters

| PARAMETER | VALUE |

|---|---|

| Sheet metal types | galvanized, hot-formed (the so-called black), acid-resistant, stainless |

| Material | S350GD, S390GD, S450GD, S235, S355, 1.4301 |

| Thickness [mm] | 1,5 / 1,75 / 2,0 / 2,5 / 3,0 / 4,0 |

| Geometry | according to Schrag catalogues/acc. to customer's documentation |

Benefits of using cold-formed purlins:

- low weight

- high strength

- good resistance to corrosion

- ease of assembly

- possibility to use in difficult external conditions

- efficient logistics

- elements drilled during production

Selection of purlins

Call

+48 42 211 37 20

Additional services

Within the confines of our production activities, in addition to bending sections, we also provide additional services. To meet the expectations of our customers, we also offer making assembly or technological holes, as well as undercuts and bevels. In addition, at the customer’s request, we organize painting of elements and their transport.

Schrag in numbers

Cold-formed purlins

Catalogue of "Schrag" purlins

Purlin weight calculator

At the customer's request, we make transoms following the submitted documentation

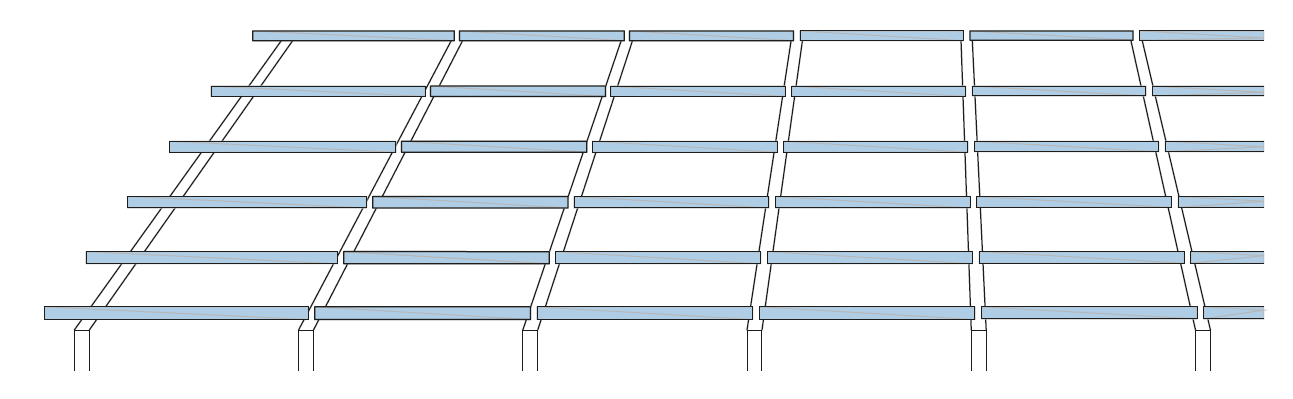

Cold-formed purlins can be used as single and multi-span beams.

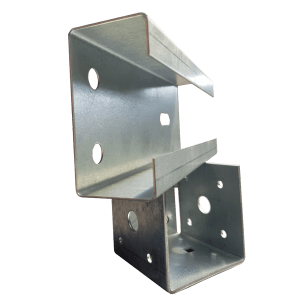

Single-span purlins

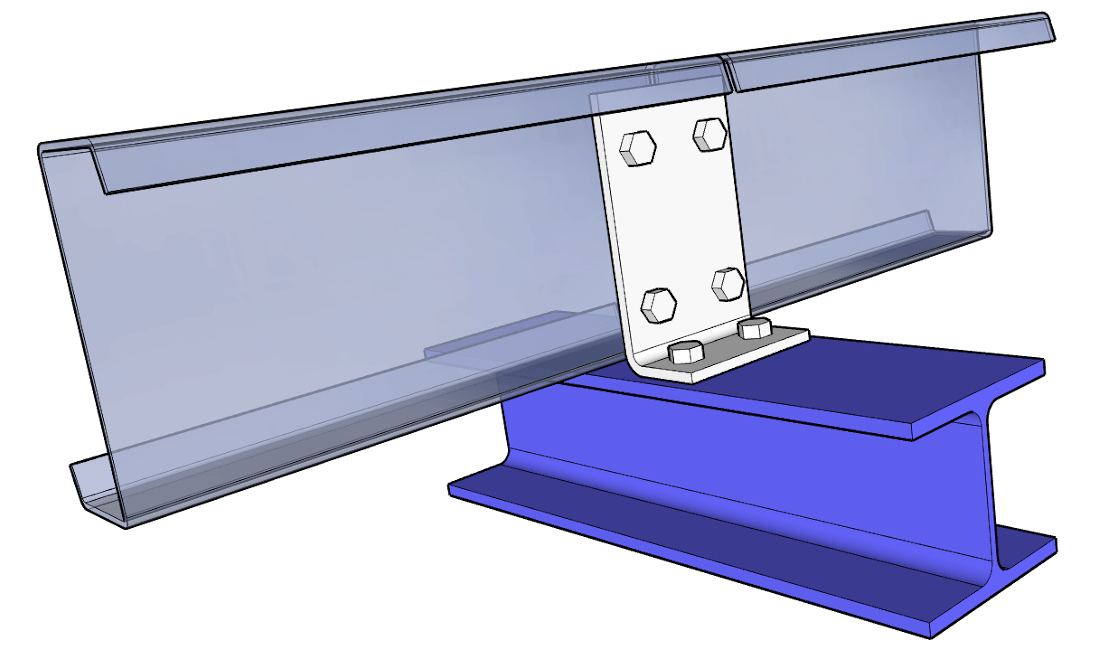

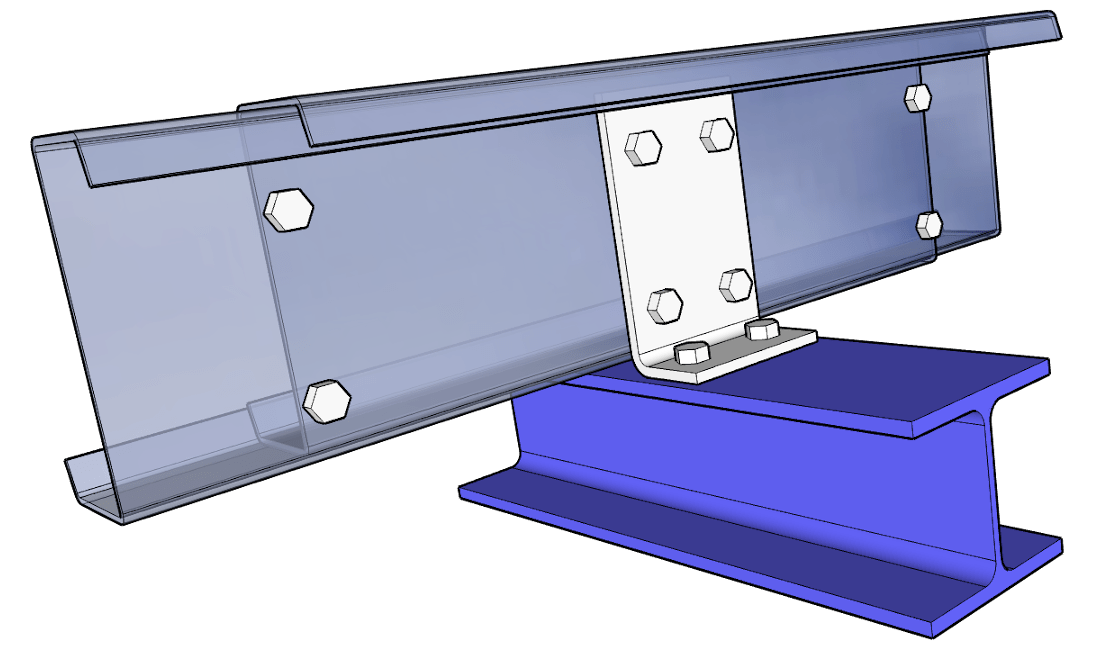

Single-span purlins are most often used in the case of small spans of beams, as well as when the girders of the building structure have irregular spacing. Single-span purlins are fixed on the transoms of the frames or between them by means of fastening elements (tables, saddles).

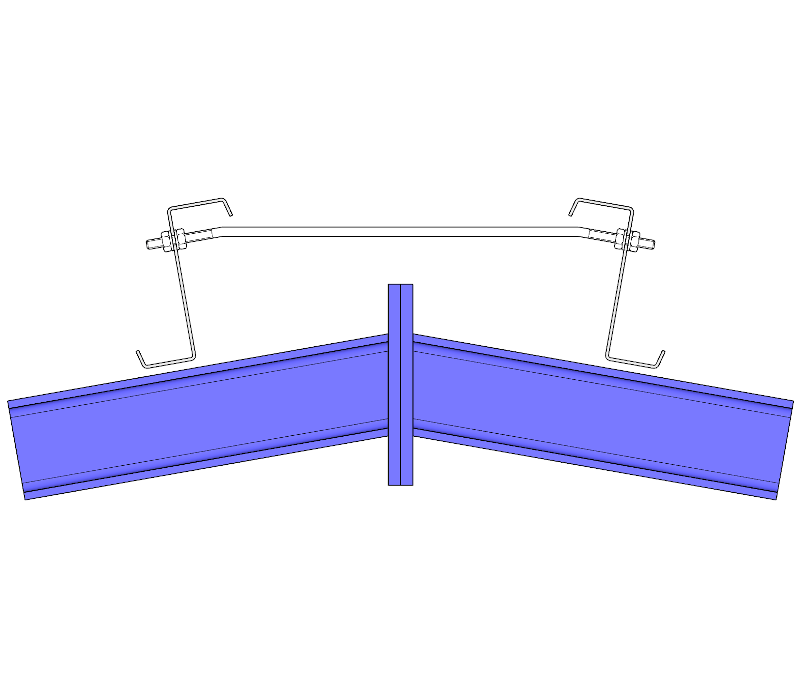

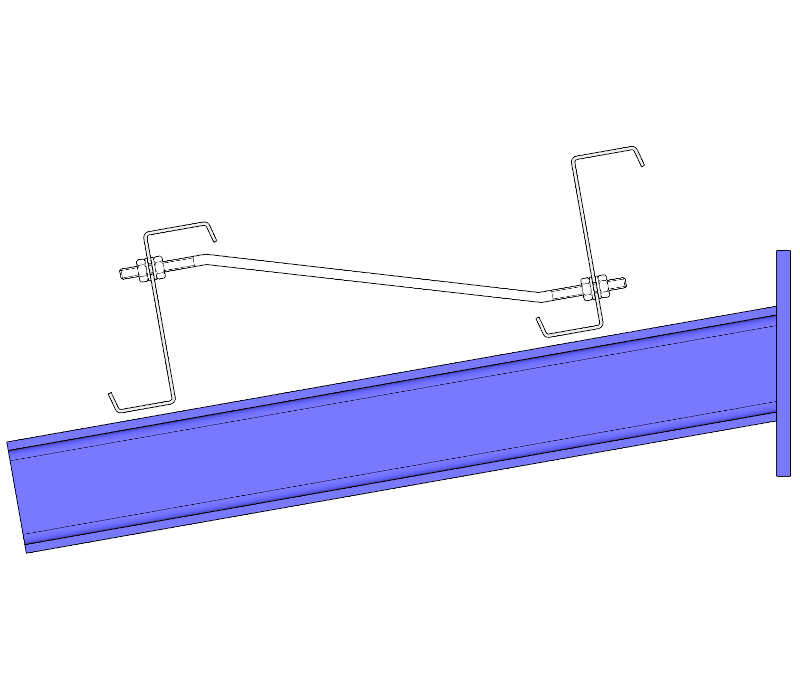

Purlins in a multi-span arrangement

Multi-span purlins are the best solution for long buildings with regular spacing of main structure frames. The purlins are mounted to the girders using fastening elements (tables, saddles). The appropriate geometry of the Z-profiles and the rotation of every second section by 180° allows to make overlaps of the appropriate length over the supports, thanks to which we obtain a continuous beam of any length. By using purlins made of thinner sheet metal in the inner bays than in the outer bays, we can significantly reduce the weight of the entire structure.

Organization of transport

Organization of transport Contact

Contact Powder coating

Powder coating