CONTAINER PROFILES

Our solutions for modular construction

Cold-formed profiles and sections are excellent construction elements. Undoubtedly, the relatively low weight, as well as the possibility of drilling any holes during production, make them easy to install. Certainly, the relatively low price is another advantage in favour of using this type of elements. The subject of the greatest care of our company is the quality of our products and services. Undoubtedly, the Schrag brand is primarily a synonym of high quality and great technological capabilities in the production of cold-formed sections. All stages related to the production of products and the provision of services, from the technical staff, through technical equipment and the materials used, are focused on achieving the best quality results. We try to act effectively, achieving the highest quality at optimal production cost. We offer our customers a modern product, exactly what they need and probably the best on the market.

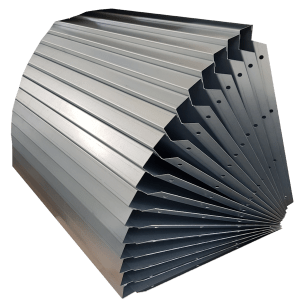

CONTAINER SECTIONS

Steel container profiles are made of raw (black) and galvanized sheets, using cold bending technology. They are used to manufacture steel container frames. Container profiles are most often made of hot-formed (the so-called black) S235 or S355 sheet due to its welding properties, which are important at the later stages of container manufacture. The cross-section of the profiles most often has C, U or L shape with sheet wall thickness ranging from 0.75 to 4.00 mm. They can be produced in lengths of up to 12.5 m with special drilling, bevelling, undercuts and technological cut-outs. The technologies we use enable the production of even single elements with very individual cross-sectional shapes adapted to even rigorous design requirements.

Sheet metal parameters

| PARAMETER | VALUE |

|---|---|

| Material | S235 / S355 / DX51D / S350GD / S390GD |

| Maximum length [mm] | 12500 |

| Thickness [mm] | 0,75 / 1,0 / 1,25 / 1,5 / 2,0 / 2,5 / 3,0 / 4,0 |

| Geometry | according to customer's documentation |

Schrag in numbers

Container profiles

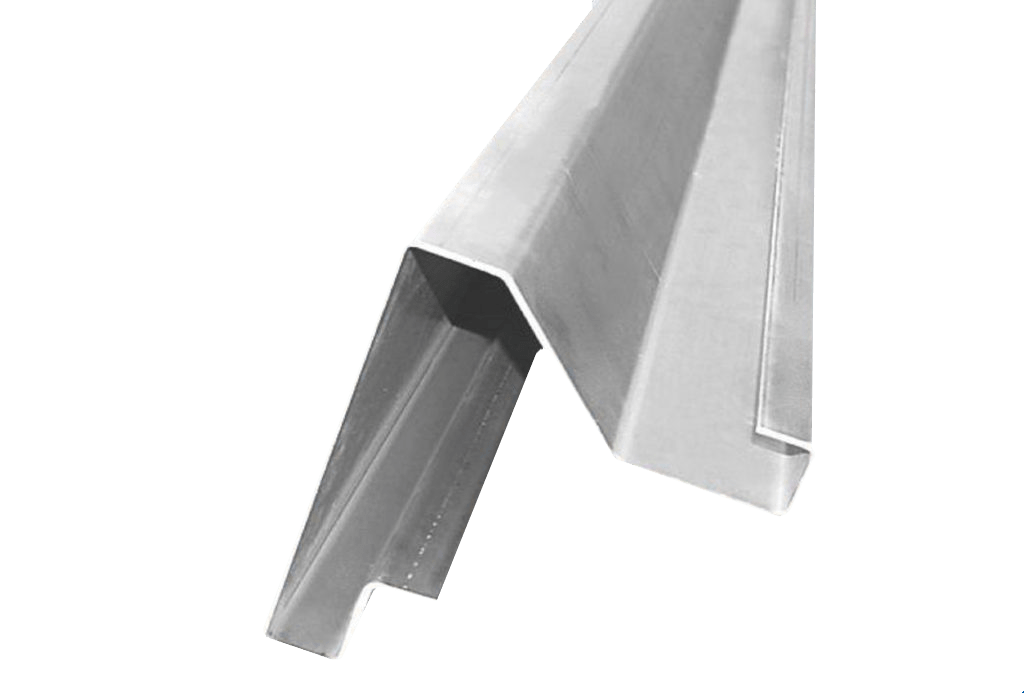

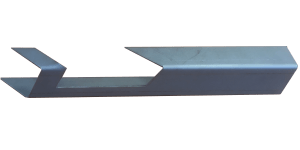

Upper perimeter gutter

One of the cold-formed container profiles is the upper circumferential gutter. Its complex cross-sectional shape makes it both a load-bearing element of the container frame and, additionally, a circumferential gutter that collects and drains water from the roof.

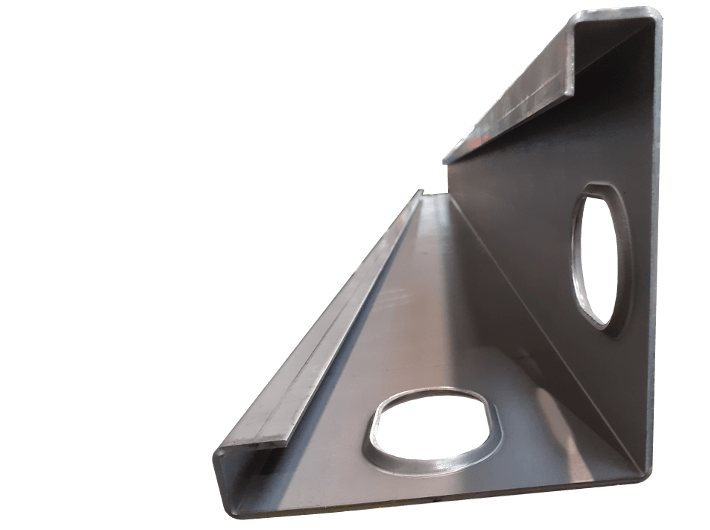

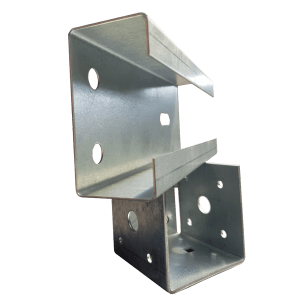

Uprights

Another cold-formed container profile are uprights. Gutters are made of thicker sheet metal than the upper beams because they have to transfer higher loads, mainly compression related. At the ends there are special oval holes with a rolled edge to facilitate the transport of the container.

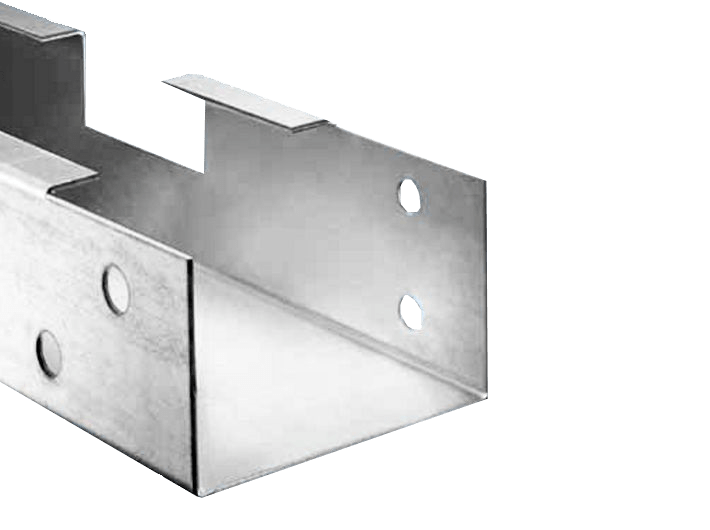

Lower perimeter beam

Another cold-formed container profile is the lower perimeter beam. In cross-section, it is usually C-shaped. Undercuts or holes made in it depend on the container floor structure.

Transport holes

The functionality of the container is also influenced by the possibility of easy and quick transport. Special oval holes with a rolled edge made directly at the ends of the uprights are helpful. Rolled edges makes the sheet in these places additionally reinforced and there is no need to install additional transport lugs.

Container profile calculator

The following request for quotation form only allows the use of the BASIC configuration of the container frame.

If you are interested in other shapes or other dimensions please send a message to office@schrag.pl.

After completing the form, it will be sent to the sales department, where an initial offer will be prepared for you.

More information about container profiles at www.profilekontenerowe.com

Additional services

Within the confines of our production activities, in addition to bending sections, we also provide additional services. To meet the expectations of our customers, we also offer making assembly or technological holes, as well as undercuts and bevels. In addition, at the customer’s request, we organize painting of elements and their transport.

Organization of transport

Organization of transport Contact

Contact Powder coating

Powder coating