COLD-FORMED SECTIONS

Freedom of shapes

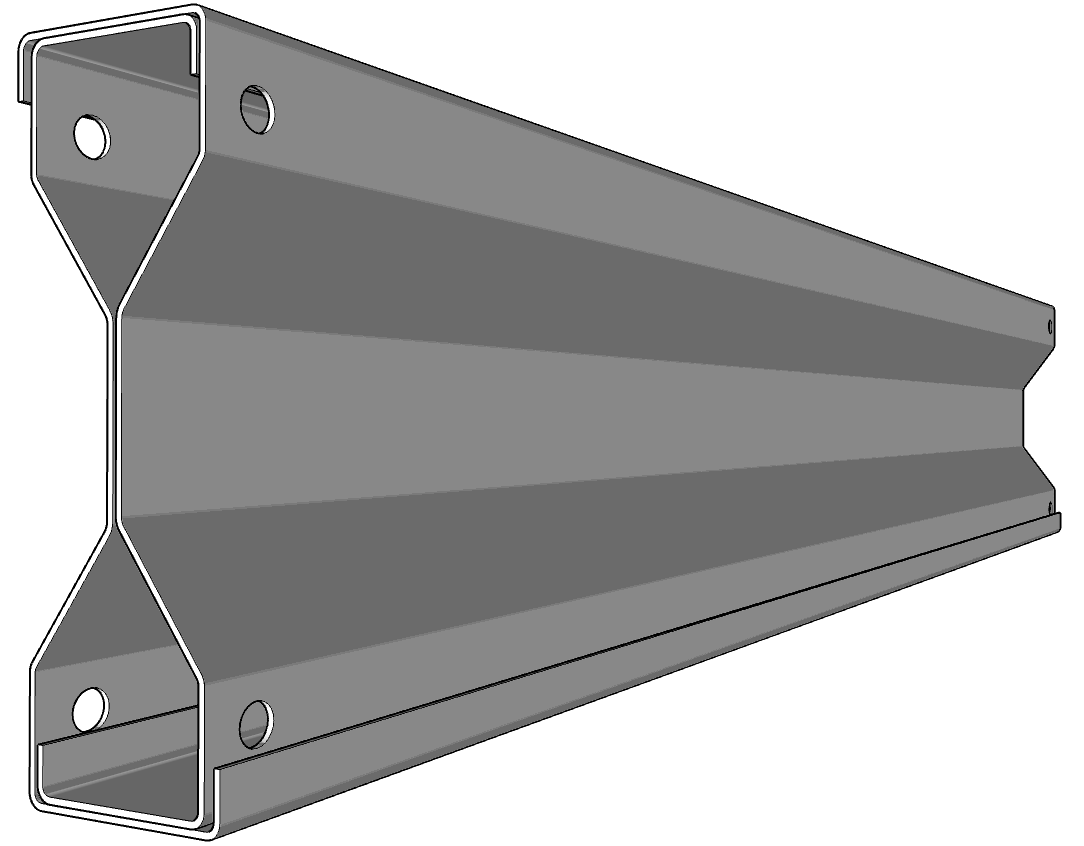

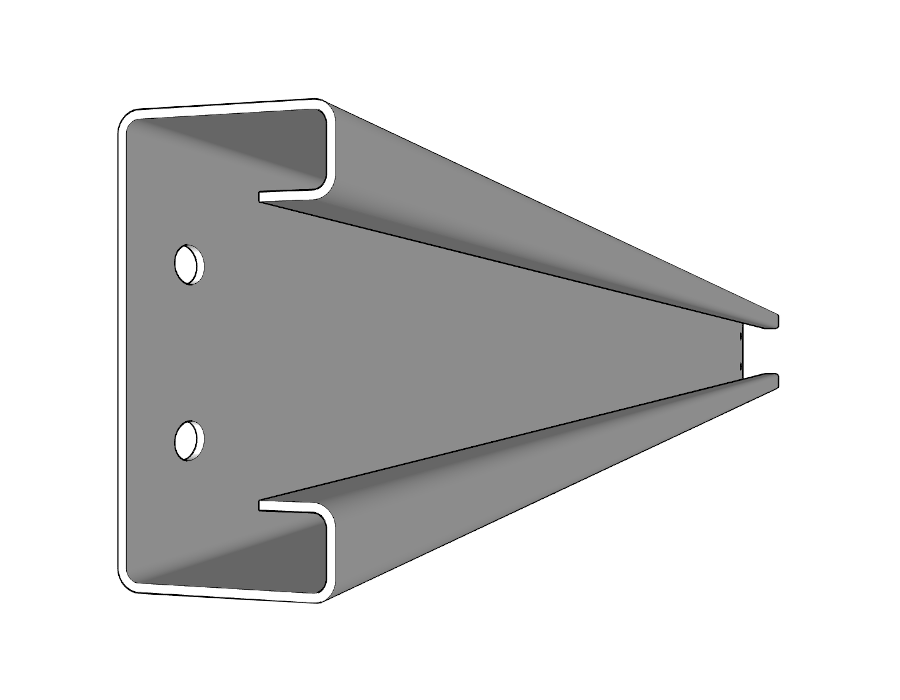

Σ-profile

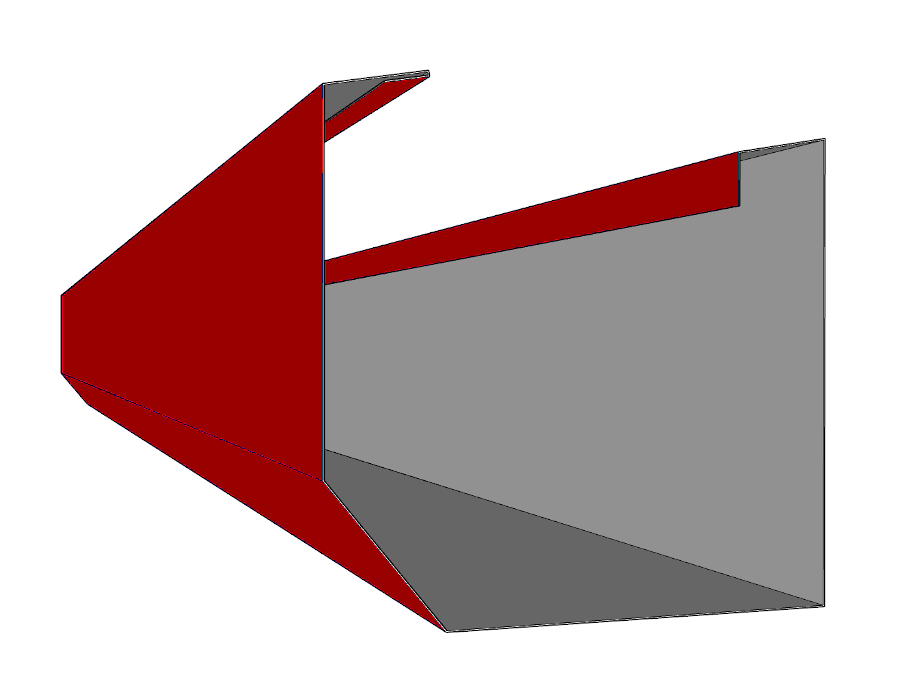

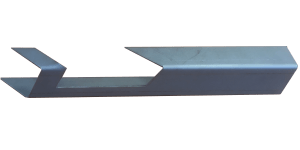

G-profile

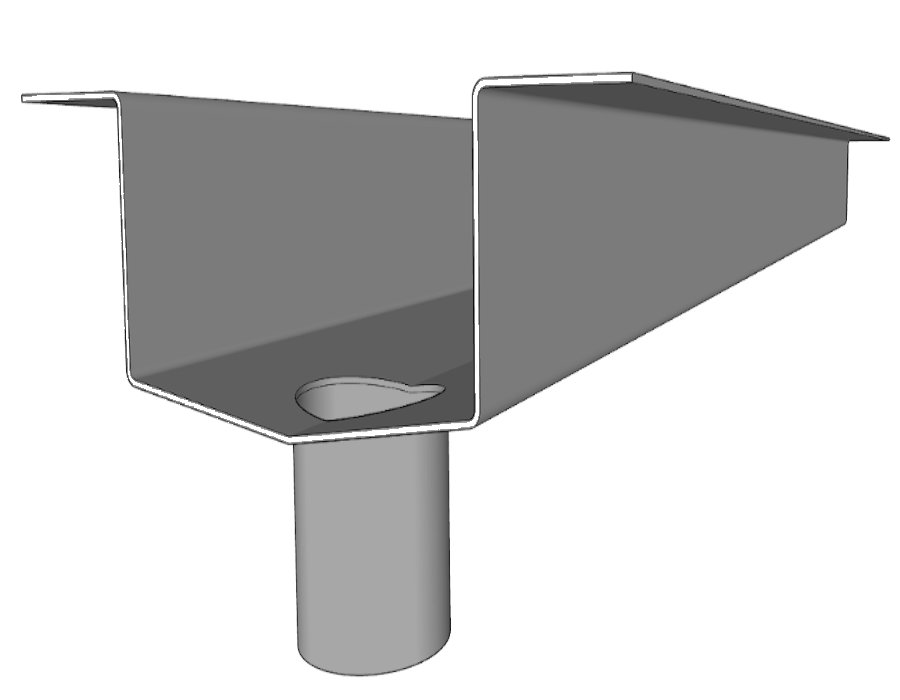

Gutter

Σ-profile upright

Trust many years of Schrag’s experience in the production of cold-formed sections from steel and aluminium sheets for industrial and commercial construction, as well as for many other sectors. We leave at the disposal of our customers our experienced team of specialists who will provide technical support both at the stage of preparing the offer and during the execution of the order. Schrag is also a design office that performs static and strength calculations of cold-formed steel sections intended for structural elements for the construction industry.

Sheet metal parameters

| PARAMETER | VALUE |

|---|---|

| Sheet metal types | galvanized, galvanized coated, hot-formed (the so-called: black), aluminium, acid-resistant, stainless |

| Material | DX51D, S350GD, S390GD, S450GD, S235, S355, 1050A, 5005A, 5754, 1.4301, |

| Maximum length [mm] | 16400 |

| Thickness [mm] | 0,5 / 0,7 / 0,75 / 1,0 / 1,25 / 1,5 / 1,75 / 2,0 / 2,5 / 3,0 / 4,0 |

| Geometry | according to customer's documentation |

| Colours | according to RAL |

Fast and reliably? It works with us!

- short delivery time

- large selection of steel sheets

- market prices

- large selection of colours

Benefits of using cold-formed transoms:

- low weight

- high strength

- good resistance to corrosion

- ease of assembly

- possibility to use in difficult external conditions

- efficient logistics

Our products have CE certificates in accordance with the European standard PN EN 1090. High standards of workmanship and internal production control guarantee the high quality expected by our customers. Continuous development and optimization of our modern machine park, as well as continuous improvement of qualifications by our employees allows us to meet the expectations of the most demanding customers.

At present, sections and cold-formed elements are used in many areas. Undoubtedly, the largest recipient of this type of products is the industrial construction industry. Cold-formed Z-, C- and Σ-sections are excellent structural elements used as roof purlins, wall transoms and eaves transoms. Increasingly, cold-formed profiles are used as substructures for the installation of windows and doors in industrial facilities. Noteworthy are also self-supporting bases for continuous skylights made of cold-formed sections, which are unrivalled for investors looking for proven and optimum solutions. Recently, cold-bent profiles have also been used in the construction of photovoltaic farms, where they are not only the optimum solution in terms of profitability and logistics, but also allow for quick assembly without the need for technological breaks.

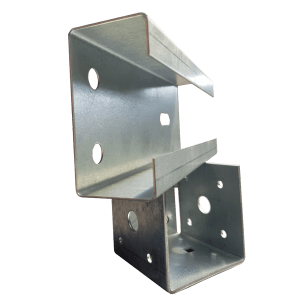

Our offer also includes sections used as construction of load-bearing frames of containers. Due to the need for further processing, e.g. welding, these elements are made of hot-formed steel (the so-called black) sheets. Container profiles proposed by Schrag are well-thought-out solutions.

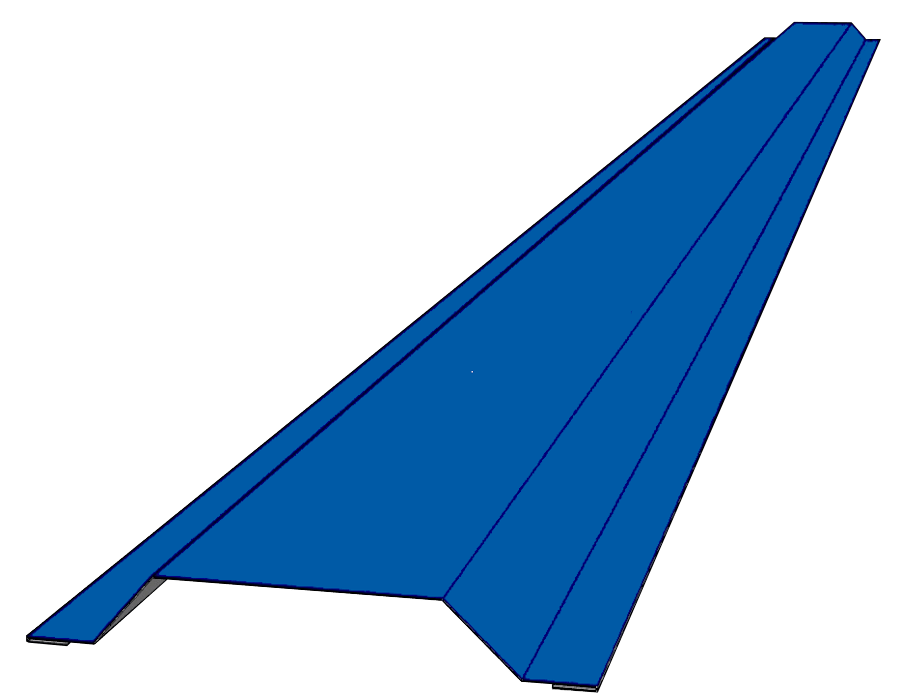

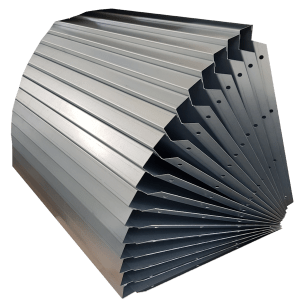

Cold-formed sections can also successfully perform a decorative function. These are mainly flashings and façade elements, i.e. coffers and panels. They are usually made of galvanized steel sheet coated with protective coats in colours from the RAL palette. The most commonly used is a polyester coating. In addition, finishing elements are also made of powder-coated galvanized steel sheet and aluminium sheet.

The methods of use of cold-formed sections is limited only by the imagination of our customers. Highly qualified staff and a modern machine park give us the ability to manufacture increasingly complex elements, as well as to process them during the production by drilling holes and making various types of undercuts. Thanks to the production technology applied, we deliver ready-to-install products in both wholesale and retail quantities.

Additional services

Within the confines of our production activities, in addition to bending sections, we also provide additional services. To meet the expectations of our customers, we also offer making assembly or technological holes, as well as undercuts and bevels. In addition, at the customer’s request, we organize painting of elements and their transport.

How much does a section weigh???

Calculate…

Step 1

Step 2

Calculate

Step 3

Organization of transport

Organization of transport Contact

Contact Powder coating

Powder coating