WALL TRANSOMS

Types of steel transoms

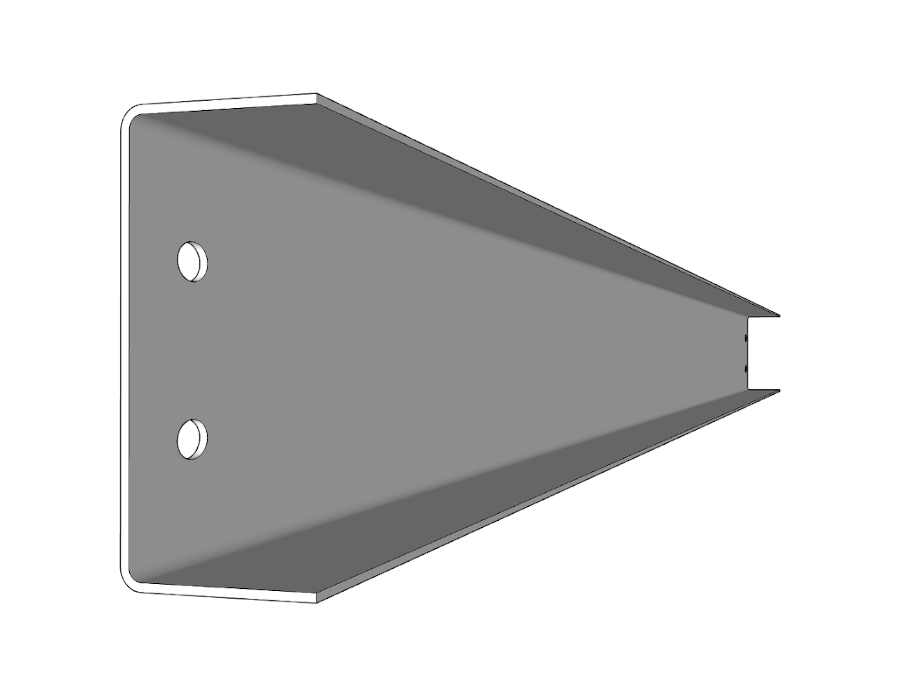

U-profile

This is the simplest variety of U-profiles (2x bent U-profile). These sections are used as wall transoms with small spans, but most often they are used as replacement elements for the assembly of joinery.

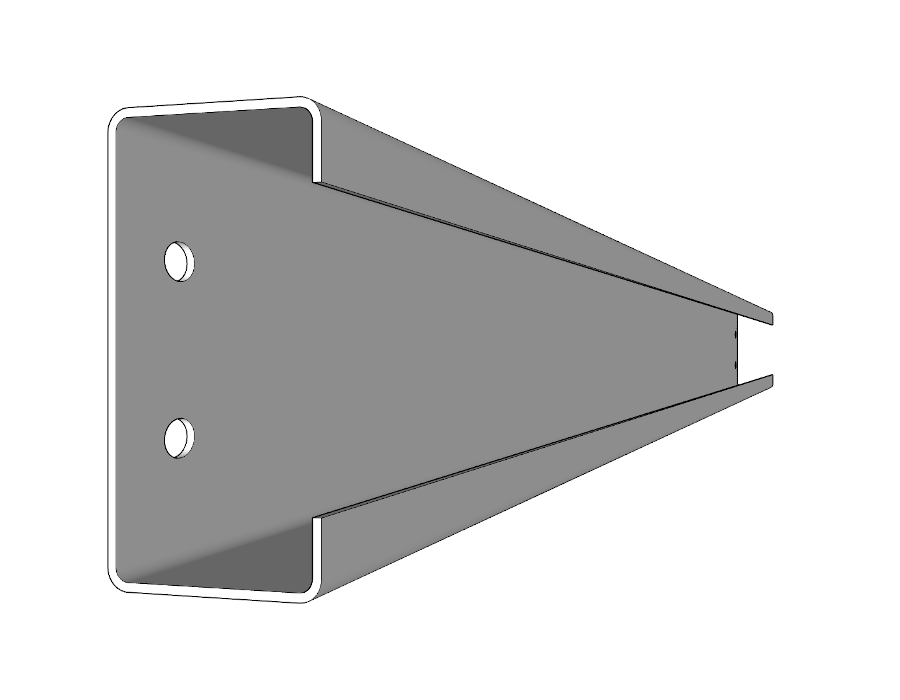

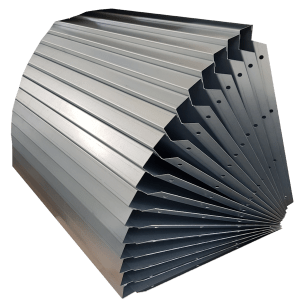

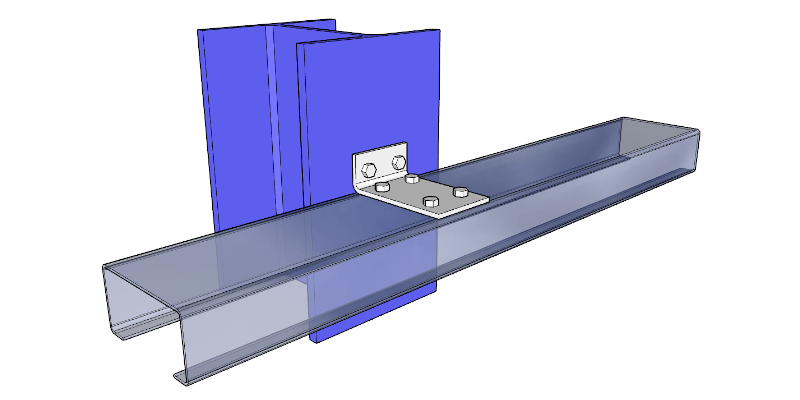

C-profile

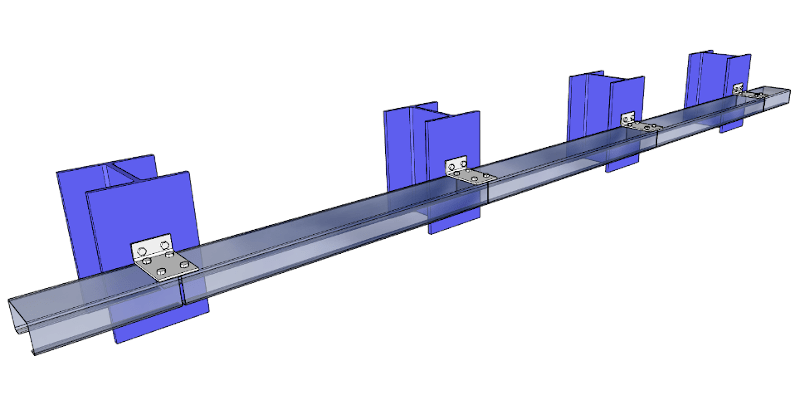

C-profiles (4x bent C-profile) are most often used as wall transoms. They are installed in a horizontal position in a single-span system, both between and to the face of the uprights.

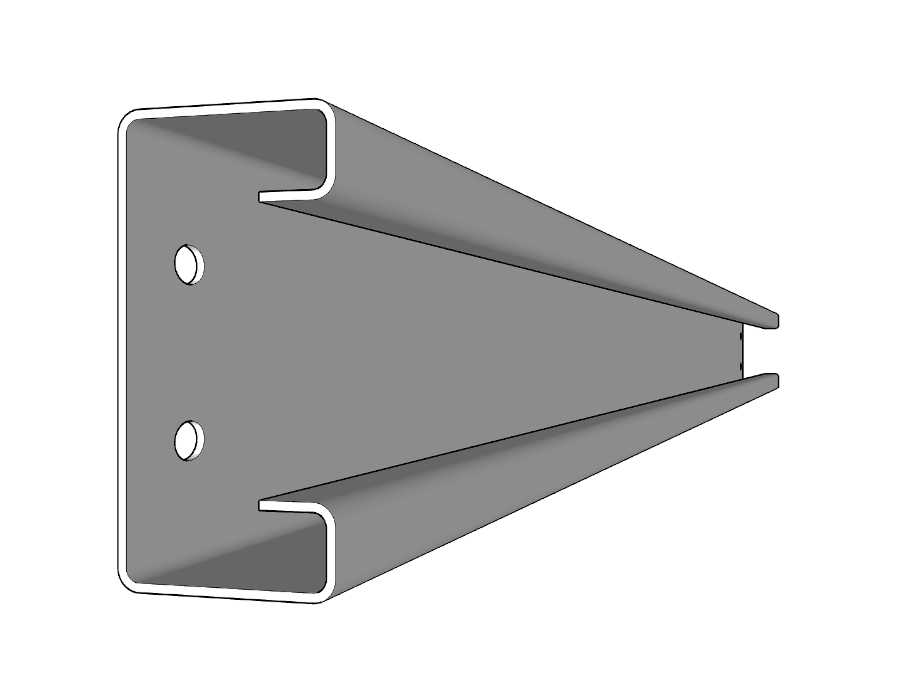

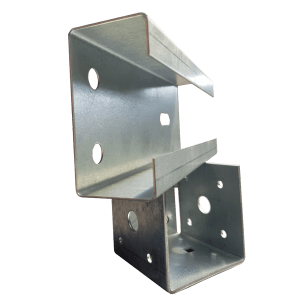

CL-profile

CL-profiles (6x bent C-profile) offer the same benefits as C-profiles, but due to the additional bends, they have an increased load capacity.

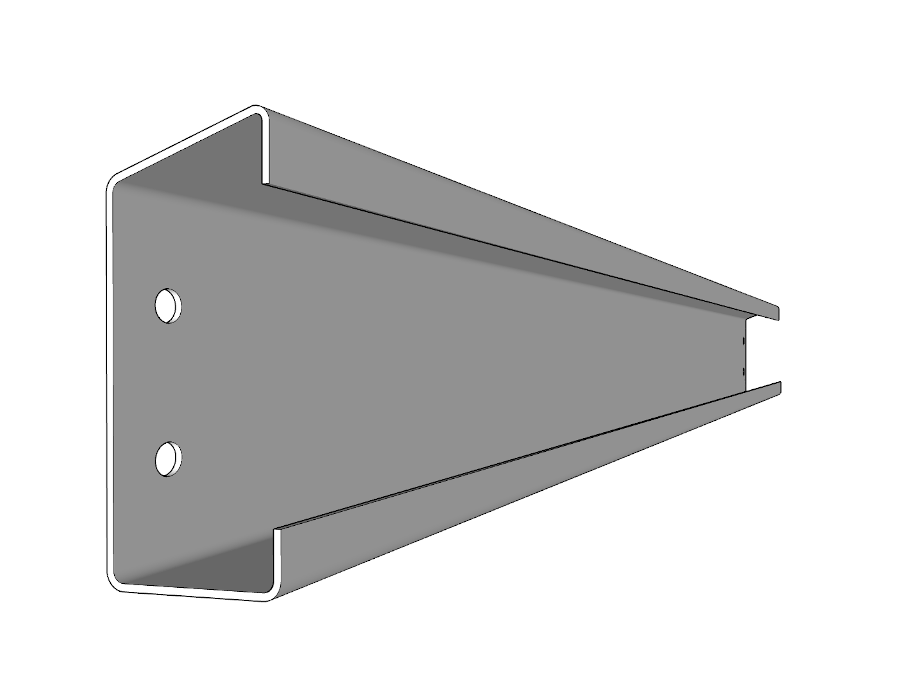

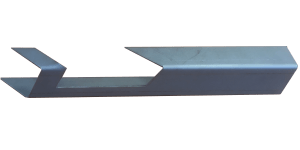

T-profile

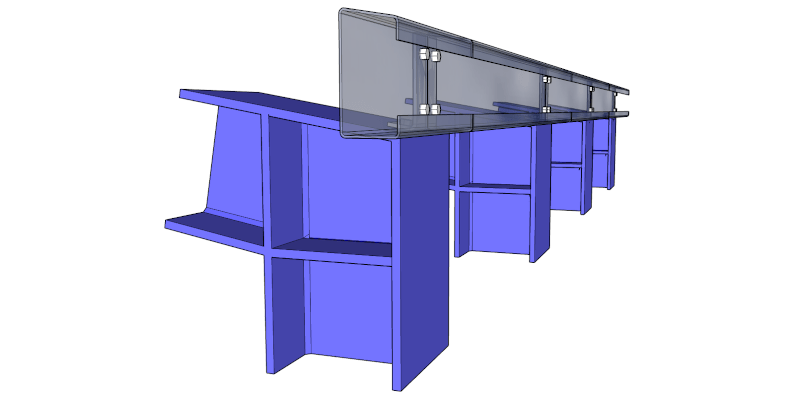

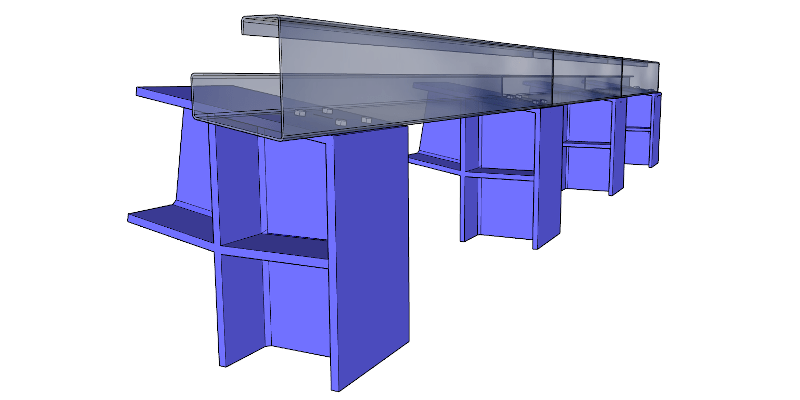

T-profile (for eaves) is a modified C-section fully adapted to simultaneously perform the function of a roof purlin and a wall transom within the eaves.

One of the most commonly used cold-formed sections are C-profiles. They come in several options, depending on the application and the expected strength parameters. These sections are most often used as single-span wall transoms. They are also successfully used as roof purlins or container profiles. The type of transom cross-section used is closely related to the required load capacity and cost-effectiveness of the solution.

The exception is the eaves transom, which is usually made of a profile bent four times with the upper shelf bent so as to adjust it to the angle of the roof slope. This profile simultaneously serves as a roof purlin and a wall transom, transferring loads in two planes.

If you need a profile with dimensions other than those specified in the Schrag catalogues, please contact our design office, which, thanks to an individual approach to each project, proposes the most effective solutions, which most importantly are following applicable standards and technical knowledge.

What distinguishes our company:

- High dimensional accuracy of steel transoms obtained through the use of state-of-the-art unrolling and profiling devices, punching machines and CNC press brakes

- Own design team with extensive knowledge and experience in the field of static and strength calculations of cold-formed profiles

- Possibility of marking with the CE mark in accordance with the PN EN 1090 standard

- Deliveries following the construction schedule

Production lengths up to 16,400 mm.

To optimize the design and selection of purlins, you can use our software Schrag Lite >>.

Sheet metal parameters

| PARAMETER | VALUE |

|---|---|

| Sheet metal types | galvanized, hot-formed (the so-called black), acid-resistant, stainless |

| Material | S350GD, S390GD, S450GD, S235, S355, 1.4301 |

| Thickness [mm] | 1,5 / 1,75 / 2,0 / 2,5 / 3,0 / 4,0 |

| Geometry | according to Schrag catalogues/acc. to customer's documentation |

Benefits of using cold-formed transoms:

- low weight

- high strength

- good resistance to corrosion

- ease of assembly

- possibility to use in difficult external conditions

- efficient logistics

- elements drilled during production

Selection of transoms

Call

+48 42 211 37 20

Usługi dodatkowe

W zakresie naszej produkcji oprócz gięcia kształtowników wykonujemy również usługi dodatkowe. Aby sprostać oczekiwaniom naszych Klientów oferujemy również wykonywanie otworów montażowych lub technologicznych, a także podcięć i ukosowań. Ponadto, na życzenie Klienta organizujemy malowanie elementów oraz transport.

Schrag in numbers

Wall transoms

Organization of transport

Organization of transport Contact

Contact Powder coating

Powder coating